To JB Straubel, innovation doesn’t end at production – it begins again at recovery. While most clean‑tech innovation celebrates new factories, new batteries, and new vehicles, Straubel is innovating at the other end of the lifecycle. Through Redwood Materials, he is redefining battery recycling as a core industrial system – one capable of reshaping supply chains, reducing geopolitical risk, and making electrification truly sustainable.

Key Takeaways

- Innovation at scale increasingly depends on system design, not just new technology breakthroughs.

- Circular supply chains can reduce cost, risk, and environmental impact simultaneously.

- Treating waste as infrastructure unlocks new economic and strategic advantages.

- Long-term sustainability requires integrating end-of-life planning into product innovation from day one.

- Industrial resilience in clean energy will be defined by who controls material recovery, not just who builds the most products.

Problem: The Hidden Bottleneck of the EV Revolution

Electric vehicles and energy storage systems depend on a small set of critical minerals: lithium, nickel, cobalt, and copper. Over the last decade, demand for these materials has surged faster than mining capacity, raising concerns around cost volatility, environmental damage, and supply‑chain concentration.

The industry’s early response focused almost entirely on extraction – finding new mines, securing overseas supply, and accelerating raw material production. But mining is slow, capital‑intensive, and politically sensitive. As EV adoption accelerates globally, this approach alone cannot keep pace.

A second-order challenge has also begun to surface: timing. Battery volumes are scaling far faster than recycling infrastructure, creating a growing mismatch between material demand and recovery capability. This lag threatens to turn today’s clean-energy boom into tomorrow’s resource crunch.

JB Straubel, the Founder and CEO of Redwood Materials, saw a different constraint emerging: batteries were being treated as disposable endpoints rather than renewable assets. Millions of devices, vehicles, and industrial systems were quietly accumulating vast amounts of recoverable material. The innovation opportunity was not just technological – it was systemic.

Solution: Building a Circular Battery Economy

Redwood Materials was founded on a simple but radical premise: the most scalable source of battery materials is not the ground, but the products already in circulation. Instead of competing with mining, Redwood aims to complement – and eventually reduce reliance on it – by turning end‑of‑life batteries into a domestic, closed‑loop supply.

The innovation lies less in any single breakthrough process and more in integration. Redwood combines collection logistics, advanced recycling, refining, and manufacturing inputs into one vertically aligned system. Batteries are not merely dismantled; they are transformed back into high‑purity materials that can re‑enter battery production with minimal quality loss.

Crucially, Redwood’s model is designed for scale from day one. Processes are engineered to handle millions of units, not pilot volumes, ensuring that circularity keeps pace with the growth of EVs and grid storage rather than trailing behind it.

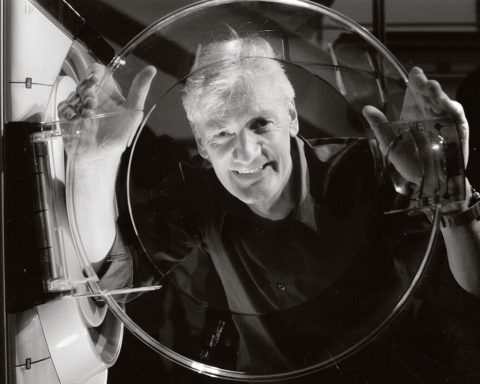

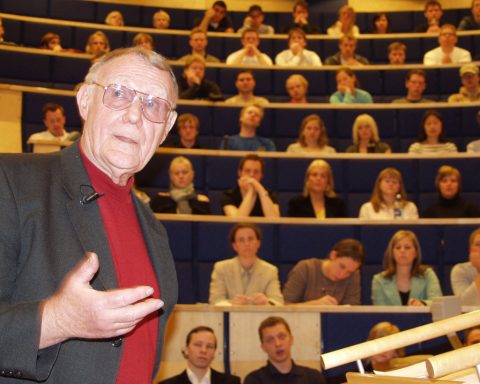

JB Straubel’s background made this approach possible.

As a Tesla co‑founder and former CTO, he understood battery chemistry, manufacturing constraints, and automotive scale. He also understood where inefficiencies hide – between suppliers, recyclers, and manufacturers that rarely operate as one system.

Rather than positioning recycling as an afterthought, Redwood treats it as industrial infrastructure. The company works directly with automakers, electronics manufacturers, and battery producers, embedding recycling into the lifecycle from the start. This shift turns sustainability from a moral argument into an economic one.

Impact: Reshaping Supply Chains, Economics, and Risk

The implications of Straubel’s innovation extend far beyond recycling. By localizing material recovery, Redwood reduces dependence on global mining supply chains that are vulnerable to political disruption and environmental regulation. This creates resilience for manufacturers while stabilizing long‑term costs.

Economically, circularity changes the unit economics of batteries. Recovered materials require less energy and water than newly mined equivalents, lowering both environmental impact and production expense. As volumes scale, recycling becomes not just cleaner – but cheaper.

There is also a strategic impact. Governments and manufacturers increasingly view battery materials as critical infrastructure. Redwood’s model aligns clean energy goals with national industrial policy, making sustainability compatible with competitiveness.

Most importantly, Straubel’s approach reframes innovation itself. Progress is no longer measured only by what is new, but by how intelligently systems reuse what already exists.

Circular Systems as the Next Industrial Advantage

As electrification accelerates, the companies that control material loops – not just products – will hold long‑term advantage. Straubel’s vision suggests a future where battery supply chains resemble ecosystems rather than linear pipelines.

In this world, innovation is quieter but more durable. It happens in logistics, in recovery rates, in chemistry optimization, and in partnerships that collapse traditional industry boundaries. Redwood Materials is an early blueprint for this shift, but its influence will likely extend across energy, manufacturing, and resource management.

Over time, circularity may become a prerequisite rather than a differentiator. As costs, regulation, and material scarcity converge, Straubel’s model hints at how future industrial leaders will be built – by mastering reuse as skillfully as production.

Straubel’s work reminds us that the most important innovations often appear after the spotlight moves on – when systems mature and hidden constraints surface. The clean‑energy transition will not be won by production alone. It will be secured by those who close the loop.

FAQs

Who is JB Straubel?

JB Straubel is a co-founder and former CTO of Tesla and the founder of Redwood Materials, a company focused on building a circular supply chain for battery materials. He is widely regarded as one of the key figures translating clean-energy vision into scalable industrial systems.

What problem is Redwood Materials solving?

Redwood addresses the growing shortage and environmental cost of battery materials by recovering and refining critical minerals from end-of-life batteries and electronics. Its approach helps close the gap between soaring EV demand and limited global mining capacity.

Why is battery recycling important for EV adoption?

Recycling reduces reliance on mining, lowers production costs, and helps secure long-term material supply as EV demand continues to rise. Without large-scale recycling, material constraints could slow or destabilize the transition to electric transportation.

How is Redwood different from traditional recyclers?

Rather than focusing only on disposal, Redwood integrates recycling directly into battery manufacturing supply chains, producing materials ready for reuse at industrial scale. This positions recycling as a value-creating input, not an end-of-life expense.

Why is JB Straubel’s approach considered innovative?

Straubel reframes recycling as core industrial infrastructure, aligning sustainability with economics, scale, and long-term competitiveness rather than treating it as a compliance function. This shift makes circularity a strategic advantage instead of a regulatory obligation.

Sources:

- https://en.wikipedia.org/wiki/J._B._Straubel

- https://www.cnbc.com/2025/08/05/tesla-co-founder-jb-straubel-taps-old-ev-batteries-for-ai-data-centers.html

- https://www.wired.com/story/the-race-to-crack-battery-recycling-before-its-too-late/

- https://www.redwoodmaterials.com/resources/sustainable-battery-materials/